|

|

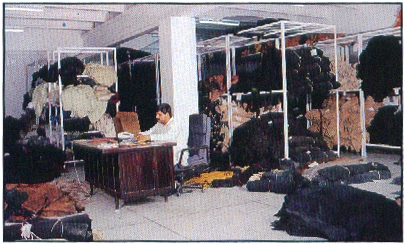

LEATHER STORE

A store with capacity of 10000 sqft. Leather well organized and situated close to the production department with easy approach, so that lots can be issue on time & carefully under the inspection if leather experts to maintain the incoming leather grades and quality according to Weavers Moto Riders standards

MATERIAL STORE

All the material used in manufacturing are kept in a separate store with an organized inventory control system and an efficient ‘issue and receipt ‘procedure is maintained as per requirement

|

|

|

|

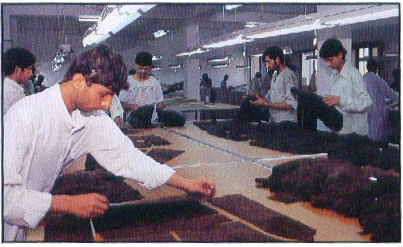

CUTTING SECTION

The cutting section comprising of expert leather cutters is in progress with an average of 300 garments per day of finished leathers or 100 garments of split suede & other split leathers.

|

|

|

|

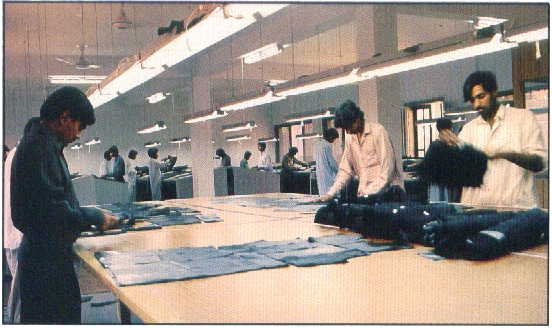

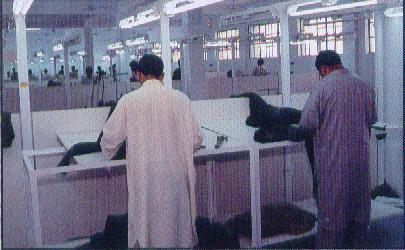

ROLL CHECKING SECTION

After cutting, the company has a roll checking system, where professionally trained people spread each cutting of the leather garments on the table to match their shades and grains in order to minimize the leather faults before sending them to the fusing section.

|

|

|

|

FUSING SECTION

For smooth and fine stitching of garments, fusing tape is heat pasted on the reverse side of leather.

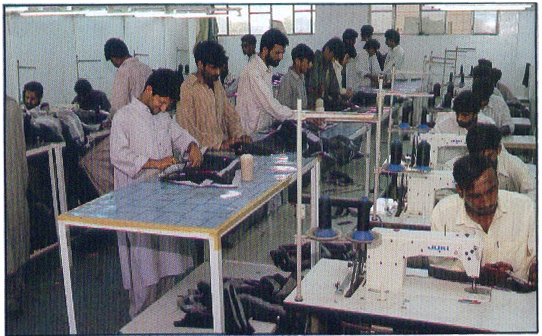

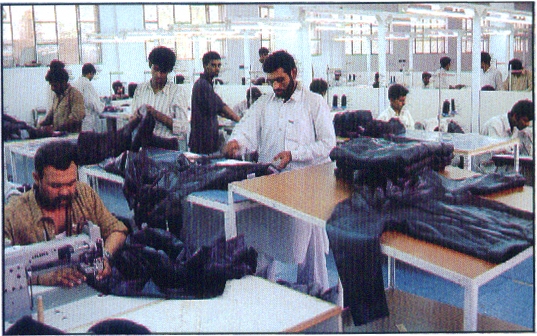

STITCHING SECTION

The key of process in garments manufacturing is divided into two sections

Chain System

To improve the rate of production, while maintaining the quality of stitched garments, company has setup the modern concept of chain line system in its stitching section. We have 5 independent production lines in this chain. Each line has 15 people who are permanent employees of the company. Stitching capacity of these 5 lines is 150 garments per day.

|

|

|

|

|

|

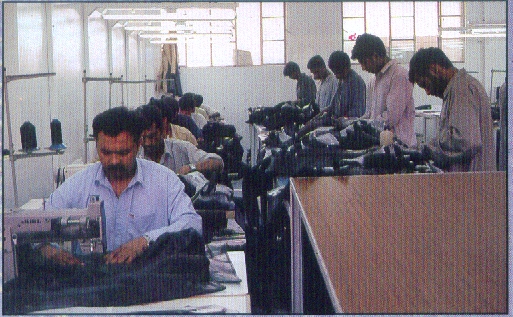

CONTRACT SYSTEM

This system is ideal for undertaking the production of smaller orders hence, still prevailing in the company since management wishes to satisfy their customers with small quantity orders also. Stitching capacity of this system is 100 garments per day.

|

|

|

|

FINISHING Two integrated jobs are performed in this section: Threading Small thread ends which are left on the garments after stitching are removed in this section to make the garments look tidy. This job is also done by expert’s workers. Buttoning The last process before a garment is declared for final inspection, buttons are sewed on or press fitted on the garments as per requirement.

|

|

|

|

FINAL INSPECTION Final inspection is supervised by highly skilled quality control panel. Quality controllers carefully inspect each garment on every measure of quality, which is the hallmark of ‘Weavers Moto Riders’

PACKING The company concentrates on the international standards of packing (sea/air) to ensure the delivery of garments in immaculate condition.

|

|

|